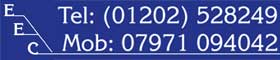

EEC Ltd are an Authorised UK Distributor of HEIDENHAIN Sealed Linear Encoders (Sealed Linear Scales)

HEIDENHAIN Sealed Linear Encoders/Scales

Sealed linear encoders – also known as sealed linear scales, from HEIDENHAIN are protected from dust, chips and splash liquids and are ideal for operation with machine tools.

EEC LTD supply, install and service HEIDENHAIN sealed linear encoders/sealed linear scales

The aluminum housing construction of the HEIDENHAIN sealed linear encoders/scales provides protection for the scale, scanning carriage – and its guideway from chips, dust, and liquids. Downward-oriented elastic lips seal the housing. The sealed linear scale scanning carriage moves along the scale via a low-friction guide and is connected to the external mounting block by a coupling that compensates unavoidable misalignment between the scale and the machine guideways.

HEIDENHAIN linear encoders/scales for numerically controlled machine tools

CNC sealed linear encoders

Sealed linear encoders (sealed linear scales) from HEIDENHAIN for numerically controlled machine tools can be used nearly everywhere. They are ideal for machines and other equipment whose feed axes are in a servo loop, such as milling machines, machining centers, boring machines, lathes and grinding machines. The beneficial dynamic behavior of the linear encoders, their high permissible traversing speed, and their acceleration in the direction of measurement predestine them for use on highly-dynamic conventional axes as well as on direct drives.

Linear scales/encoders with slimline scale housing

The sealed linear scales encoders with slimline scale housing are designed for limited installation space. Larger measuring lengths and higher acceleration loads are made possible by using mounting spars or clamping elements.

Linear encoders for manually operated machine tools

For typical applications on manual machine tools such as milling machines or lathes, display steps of 10 µm or 5 µm are sufficient. Such display steps are provided by the LS 300 and LS 600 series linear encoders with an accuracy grade of ± 10 µm per meter traverse.

Incremental Linear Encoder LS 1679 with Integrated Roller Guide

The LS 1679 has been specially developed for press brakes. The basis for its high accuracy and repeatability is its precise glass scale and high-quality integral bearing. Thanks to the material of its steel track and steel roller bearing component pair it is very robust. There are many variants for connection to the machine frame, whereby the ball coupling offers the most degrees of freedom. Besides the standard resolution with 5 µm measuring step there is also a variant with 1 µm. For perfect mounting to the two C-columns there are variants with rightward and leftward cable outlets.