HEIDENHAIN Rotary Encoder Repairs

EEC Ltd supply HEIDENHAIN rotary encoder repairs for components with or without integral bearing…

Recent EEC Ltd HEIDENHAIN Rotary Encoder Repairs

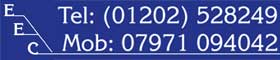

Contact EEC here for enquiries

Features of the HEIDENHAIN RON 285 C

• Incremental measuring method

• Large hollow shaft diameter (up to 60 mm)

• Integrated stator coupling

• Compact size for limited installation space

• System accuracy includes the deviation caused by the shaft connection

• Outstanding dynamic response

• Simple installation

Typical field of application

• Rotary tables

• Swivel heads

Absolute encoder – massive contamination, causing the grating disc to become

un-attached, in this case replacement is the only option.

Mounting Variants for HEIDENHAIN Rotary Encoder Repair & Replacement

HEIDENHAIN Rotary Encoders with Integral Bearing

With HEIDENHAIN rotary encoders which have an integral bearing and stator coupling, the graduated disk of the rotary encoder is connected directly to the shaft to be measured. The scan unit is guided along the shaft via ball bearings which are supported by the stator coupling. During angular acceleration of the shaft, the stator coupling must only absorb the torque resulting from friction in the bearing – thereby minimising static and dynamic measuring errors. In addition, the coupling mounted on the stator compensates axial motion of the measured shaft. Other benefits of the stator coupling are:

• Simple mounting

• Short overall length

• High natural frequency of coupling

• Hollow-through shaft possible

HEIDENHAIN Rotary encoders with an integral bearing for separate shaft coupling are designed with a solid shaft. The recommended coupling to the measured shaft compensates radial and axial tolerances. Angle encoders for separate shaft couplings permit higher shaft speeds.

HEIDENHAIN Rotary Encoders with Integral Bearing

Rotary encoders without integral bearing operate without friction. The two components – the scanning head and the scale disk, drum, or tape – are adjusted to each other during assembly. The benefits are:

• Large diameter of hollow shaft

• For high shaft speeds

• No additional starting torque