HEIDENHAIN Interface Electronics

HEIDENHAIN Interface electronics adapt the encoder signals to the interface of the subsequent electronics. They are used when the subsequent electronics cannot directly process the output signals from HEIDENHAIN encoders, or if additional interpolation of the signals is necessary.

HEIDENHAIN interface electronics are available in various mechanical designs.

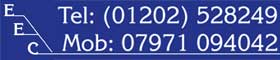

EEC Ltd are Authorised Distributors/Dealers for HEIDENHAIN Interface Electronics

HEIDENHAIN Evaluation Electronics for Metrological Applications

HEIDENHAIN Evaluation Electronics for metrological applications offer numerous functions for measured data acquisition and statistical evaluation of measured values.

QUADRA-CHEK evaluation electronics are available for profile projectors, measuring microscopes, 2-D and video measuring machines as well as CMMs. Measure points on 2-D contours, either automatically or manually by crosshairs (depending on the version), by optical edge detection or by video camera. Video camera options provide a real-time display of the live image and integrated image processing. For 3-D contours, such as planes, cylinders, cones and spheres, the measurement points are saved by probing with a touch probe.

In the optional CNC version, they also operate as fully-fledged controls for axis positioning and are capable of automatically executing measuring programs.

EEC Limted Supply, Install & Service HEIDENHAIN evaluation electronics for metrological applications

HEIDENHAIN Digital readouts for manual machine tools

HEIDENHAIN Digital readouts for manual machine tools increase productivity, saving time, increasing the dimensional accuracy of the finished workpiece via user-friendly operation.

New or used machines can be equipped with a digital readout. HEIDENHAIN digital readouts are easily retrofitted to any model of machine or type of equipment, whatever the application and number of displayed axes. Practice-oriented functions and cycles are available for various applications. The distance-to-go display feature with graphic positioning aid allows you to approach the next nominal position quickly and reliably simply by traversing to a display value of zero. And POSITIP speeds up small-batch production—repetitive machining sequences can be saved as a program.

Precise manufacturing made easy: Together with linear encoders from HEIDENHAIN, digital readouts measure the axis movements directly. Therefore, backlash caused by mechanical transfer elements such as lead screws, racks and gears – carries no influence.

EEC Limited are an authorised UK distributor of HEIDENHAIN Digital Readouts (DRO)