TNC Controls For milling machines, milling/turning machines and machining centres

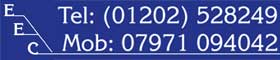

EEC Ltd are an Authorised UK Distributor/Dealer for HEIDENHAIN TNC Controls

Further detailed product info:

HEIDENHAIN TNC 640 – The Contouring Control for Milling and Milling/Turning Machines

HEIDENHAIN MANUALplus 620 – The Contouring Control for CNC and Cycle Lathes

HEIDENHAIN CNC PILOT 640 – The Contouring Control for CNC Lathes

HEIDENHAIN TNC/CNC Drives, Motors and Inverters

HEIDENHAIN 320

HEIDENHAIN iTNC 530

HEIDENHAIN TNC Controls – Technology for Demanding Positioning Tasks – Overview

- HEIDENHAIN TNC control products are a complete machine-tool-control product line sporting wide ranging features

- HEIDENHAIN TNC controls machines operating up to 18 axes

- The Klartext* conversational programming capability is suited for the workshop floor

- HEIDENHAIN TNC Controls can also be programmed externally

- HEIDENHAIN TNC Controls ere well suited for automated production

- HEIDENHAIN TNC Controls provide a smart-choice for everything from simple milling procedures to high-speed milling

HEIDENHAIN contouring control for lathes

HEIDENHAIN contouring control for lathes is the perfect solution for controlling both CNC and cycle lathe and enables familiarity of manual production, for less-complex components & parts. Contouring control supports programming using multiple cycles and the smart-turn feature offers form and graphics supported programming for the more complex part or component. Contouring control performs complementary milling and drilling operations in a single fixture and also supports vertical lathes. HEIDENHAIN contouring control is well suited for either digital or analog drive control technology.

HEIDENHAIN TNC Control Efficiency – Working Efficiently and with Process Reliability

Efficient working practices are essential for processes such as heavy machining, roughing at high cutting speed, and in the machining of hard-to-cut materials standard to aviation and aerospace industry, such as titanium alloys, nickel-based materials or stainless steel. Heavy machining primarily focuses on removing as much material as possible in the shortest time. This is where the component parts of any machining process are pushed to their limits. So for high-performance cutting, comprehensive process management is an indispensable prerequisite for quality and economy. The forces that result from the cutting process place an extreme load on the machine and tool. The goal must therefore be to optimise metal removal rates, maximise tool service life and minimise the machine load.

With the concept of Dynamic Efficiency, HEIDENHAIN offers innovative TNC functions that help the user to increase process reliability in heavy machining and roughing in order to improve efficiency.

HEIDENHAIN Dynamic Efficiency comprises these three TNC functions:

- ACC (Active Chatter Control) – This option reduces chatter tendencies and permits greater infeeds

- AFC (Adaptive Feed Control) – This option controls the feed rate depending on the machining situation

- Trochoidal milling: Cycle for the roughing of slots and pockets in a way that eases the load on the tool and the machine

HEIDENHAIN TNC Control Precision – Machining Dynamically and with High Accuracy

High productivity, lean manufacturing principles and cost reduction are preeminent goals of contemporary manufacturing. A constant drive for reduced scrap & wastage, quicker machining times, removal of unnecessary operations and in particular, removal of rework tanks, are closely related to this drive. With the potential for conflict-of-interest between machining time, quality and component/workpiece accuracy, machine tool controls must be capable of presenting an optimised solution for the machine and the manufacturing process.

Under the concept of Dynamic Precision, HEIDENHAIN describes a group of functions for TNC controls that dramatically improve the contouring accuracy of machine tools – even at high feed rates and within complex contouring moves. The dynamic accuracy of a machine tool is determined by the required acceleration of the feed-axis to achieve precise movement between the workpiece and tool.

When feed axes are accelerated, machine components can be deformed by inertia forces or subject to vibration. With Dynamic Precision, the dynamic errors at the Tool Center Point (TCP) that arise during machining are significantly reduced – enabling NC programs to run with better component accuracy and surface quality, and at noticeably faster rates.

*Easy creation of NC programs using KLARTEXT

HEIDENHAIN TNC controls are workshop oriented, which means that they were conceived for programming right at the machine. With conversational programming you can forget about memorising G codes. Instead you program using dedicated keys and soft keys, which precisely indicate the respective-associated function. With a keystroke, you initiate a HEIDENHAIN plain-language dialog, and the TNC begins immediately to support you actively in your work. Unambiguous questions and prompts help you enter all of the required information.